Mining & Lithium Industries

Elastomeric supplies for the Mining & Lithium industry.

PISTONING CUPS

UF-W CUPS: They have a treated steel wire structure, anchored with a metal base. The wire and elastomeric compound allow the cups to achieve the necessary flexibility for a perfect seal. They are completely covered with a high resistance and performance elastomer.

HPR Cups: The three-lip Guiberson type piston cups have been designed and made according to the demands of the piston process. They combine a high quality compound attached to a metal support, thus giving it greater resistance.

V Cups: These are wire-free cups with an aluminum support just like the HPR model. Their upper lips allow to automatically control the amount of load lifted. They are especially effective in wells with a high concentration of suspended sand.

application table of pistoning cups according to the tubing used

|

NOMINAL TUBING SIZE |

TUBING WEIGHT |

TUBING INSIDE DIAMETER |

OUTSIDE CUP DIAMETER |

CUP MODEL |

|

2,3/8” |

4.70 lb/ft |

1.995” = 50.97 drift = 1.901” |

1.935” = 49.15 |

UF 24 W |

|

2.7/8” |

6.50 lb/ft |

2.444” = 62.00 drift = 2.347” |

2.370” = 60.20 |

UF 35 W |

|

3.1/2” |

9.30 lb/ft |

2.992” = 76.00 drift = 2.867” |

2.904” = 73.76 |

UF 30 W |

IN ALL CASES, INDICATE DIAMETER AND WEIGHT OF THE TUBING

INSERTS FOR VALVES

They are made of different types of synthetic rubber, resistant to hydrocarbons. They are also made of polyurethane for better abrasion resistance. Compound characteristics are modified depending on the working conditions to which they will be subjected, varying the formulation according to the requests for higher temperatures or variant of mud or drilling chemicals. Suitable for high and low pressure.

PACKINGS

For the mining industry, MECANOTÉCNICA manufactures a complete range of packing systems for stems, valve caps, liners, as well as packings for wing unions such as Dresser, Victaulic snap joints and others.

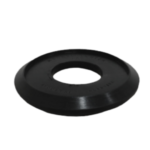

ELASTOMERIC BEARINGS

Bearings made of rubber, polychloroprene and iron sheet. Depending on the Client’s requirements, they vary in dimensions, thickness and number of sheets included. There are coated on all sides with elastomeric material with a minimum thickness of 0.09” (2.5 mm), thus preventing corrosion of the metal inside. They are called LASTO BLOCK TYPE.

They are easily installed and do not require maintenance. These bearings meet the specifications of ASTM standards. We design and develop bearings upon request, according to our Client’s drawings and specifications.

They are manufactured in various dimensions, as specified by the part designer of the requesting Client, and built with metallic inserts of different qualities.

These bearings meet the characteristics specified in the ASTM standards listed below:

- Shore A Hardness: 60 + 5

- Tensile Strength: 175 KgF/mm2

- Elongation at Break: 630 %

- Tear Strength: 14 KgF

- Compressive Strength/Permanent Deformation: 15%

- Heat Resistance: 100 ºC (212 ºF)

- Ozone Resistance: E

- 1010 sheet or sheet with specifications (according to market availability) or stainless steel

SLIDING LASTO BLOCK TYPE: Similar to the one described above with the addition of a properly treated TEFLON top sheet, manufactured in the thickness as requested by the Client.

BEARINGS ON SLOPES: These bearings are produced to special order, generally with a 1% to 6% slope in the upper face.

SEISMIC ARRESTORS: Our seismic arrestors are pieces with similar characteristics to those of our bearings, but with a single thicker metal insert.

SPECIAL ORDERS: We produce bearings according to the Client’s production drawings and specifications. We also make bearings in other types of rubber according to requirements.

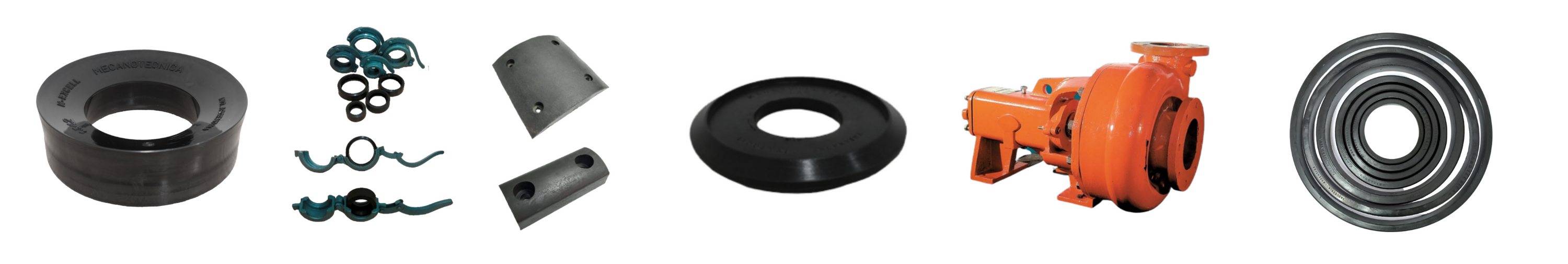

FENDERS

The fenders are made of natural rubber and EPDM. They are useful to prevent vehicles from bumping at trucking yards or unloading areas. They are commercialized in different shapes and sizes.

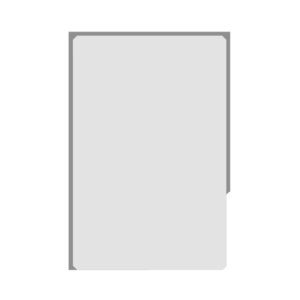

M-250 CENTRIFUGAL PUMP

Main advantages of the M-250 centrifugal pump over conventional centrifugal pumps:

- Greater resistance to abrasion, especially models whose working parts are coated in polyurethane (casing, impeller and wear plate)

- Less maintenance due to design and quality of materials

- Lubrication of the bearings in an oil bath. Oversized bearings

- Standard alloy steel shaft

- Replaceable sleeve on the shaft in the packing area

- Robustness in all its component

- Mechanical seals, with elastomeric packing option, if required

3″ x 2″ model with stainless steel volute, wear plate and impeller.